Products

15% Glass Filled and 3% MoS2 Filled PTFE Tube

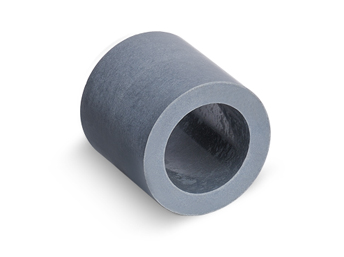

15% Glass Filled and 3% MoS2 Filled PTFE Tube reinforced with 15% glass fibres depending on the needs of the application. Glass fibre is used as a PTFE filler as it offers much improved compression and wear properties. The material may also be inert gas sintered to further improve creep properties and reduce porosity and gas permeability (there would be a consequent loss of tensile properties) With 3% MoS2 filled shows the same pressure resistance as glass-filled PTFE but uses MoS2 as a lubricant. Molybdenum also increases hardness and decreases wear

Send Inquiry

Product Description

15% Glass Filled and 3% MoS2 Filled PTFE Tube

Style KXT GU980-15-3 15% Glass Filled and 3% MoS2 Filled PTFE Tube

15% Glass Filled PTFE tube reinforced with 15% glass fibres depending on the needs of the application. Glass fibre is used as a PTFE filler as it offers much improved compression and wear properties. The material may also be inert gas sintered to further improve creep properties and reduce porosity and gas permeability (there would be a consequent loss of tensile properties)

With 3% MoS2 filled shows the same pressure resistance as glass-filled PTFE but uses MoS2 as a lubricant. Molybdenum also increases hardness and decreases wear

Advantages:

• Glass-filled PTFE rod has enhanced strength and stiffness

• Very good electrical insulation properties

• Extremely good chemical resistance.

• Improved dimensional stability

• Enhanced creep resistance

• Good sliding properties

Application:

• Pump and instrument construction

• Food and medical technology

• Chemical engineering parts

• Electrical industry

• Pump housings

• Shaft bearings

• Valve seats

Data sheet

|

Property |

Test Method |

Values |

|

Specific Gravity |

ASTM D 4894 |

2.22-2.25g/cm3 |

|

Tensile Strength |

ASTM D 4894 |

10-15 mpa |

|

Elongation |

ASTM D 4894 |

100-150% |

|

Shore D Hardness |

BS EN 13000-2 |

65-70 |

|

Temperature Range |

- |

-200 oC - 260 oC |

|

Material |

- |

15% glassfiber & 3% mos2 |